A Vessel at Risk of Failure

A leading marine commercial operator was facing persistent issues with one of the most important assets in its fleet, a dredger suffering from chronic powertrain failures and an ageing propulsion system. These recurring problems caused frequent downtime, escalating maintenance costs, and growing safety concerns.

With the vessel’s 20-year-old engine approaching the end of its service life, the operator turned to Al Masaood Power, the authorised distributor of mtu solutions in the UAE, Iraq, and Bahrain.

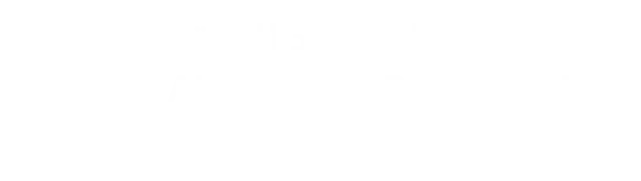

By installing an mtu 16V4000M63 engine, the project transformed the vessel’s performance, reliability, and long-term viability.

| Project | Dredger Repowering |

|---|---|

| Client | Leading Marine Commercial Operator |

| Vessel Issue | Frequent failures in Powertrain |

| Solution | Repowering with mtu 16V4000M63 |

| Outcome | Enhanced reliability, reduced noise/vibration, lower OPEX |

Understanding the Core Challenges

The dredger’s original propulsion system, a 20-year-old engine model, had reached the end of its service life. The vessel’s operational efficiency was severely compromised by a series of cascading problems and local / non-licensed repairing of some powertrain components.

Key Problems Identified

- Chronic Mechanical Failures: The vessel’s powertrain was a constant source of trouble, with specialised steel couplings failing repeatedly due to excessive vibration. This led to unplanned downtime and significant repair expenses.

- Data and Diagnostic Blackout: The outdated engine lacked modern monitoring capabilities. This “blind spot” made it impossible to perform crucial analyses.

- Scarcity of Critical Components: Sourcing spare parts for the obsolete engine became a major logistical and financial burden. Long lead times and limited availability often exacerbated repair delays, further impacting operational uptime.

| Issue | Description |

|---|---|

| Mechanical Failures | Special Steel couplings failed repeatedly due to excessive vibration and noise |

| Obsolete Engine | 20+ years old, no powertrain data for Torsional Vibration Analysis |

| Monitoring Gaps | Couldn’t track individual cylinder exhaust temps |

| Spare Parts Shortage | Difficult to source obsolete components with long lead times |

The combination of these factors created a challenging environment, characterised by reactive maintenance, high operational expenditure (OPEX), and a heightened risk of catastrophic failure.

The Repowering Solution

To overcome these systemic issues, the dredger was repowered with the mtu 16V4000M63 engine, renowned for its reliability, efficiency, and advanced digital integration.

Key Engine Specifications

- Configuration: 16-cylinder, 4-stroke

- Displacement: 76.3 litres

- Rated Power: 2,000 kW (2,680 bhp) at 1,800 rpm

- Time Between Overhauls (TBO): 33,000 hours (up from approximately 20,000 hours)

- Fuel System: Common Rail Injection – delivering optimised fuel consumption at 199 g/kWh

This was far more than an engine replacement; it was a complete modernisation of the vessel’s propulsion and monitoring systems, addressing every root cause of the previous operational challenges.

Performance Transformation

| Area | After Repowering with mtu 16V4000M63 |

|---|---|

| Operational Noise | Near-silent operation, enhancing crew comfort and reducing noise pollution |

| Engine Monitoring | Real-time digital insights via ADEC and Go Connect |

| Maintenance Strategy | Predictive and condition-based, reducing downtime |

| Parts & Support | Globally available components ensuring quick repairs |

| Engine Longevity | 33,000+ hour TBO significantly reduces lifecycle costs |

| Data & Diagnostics | Remote logging and analysis prevent critical failures |

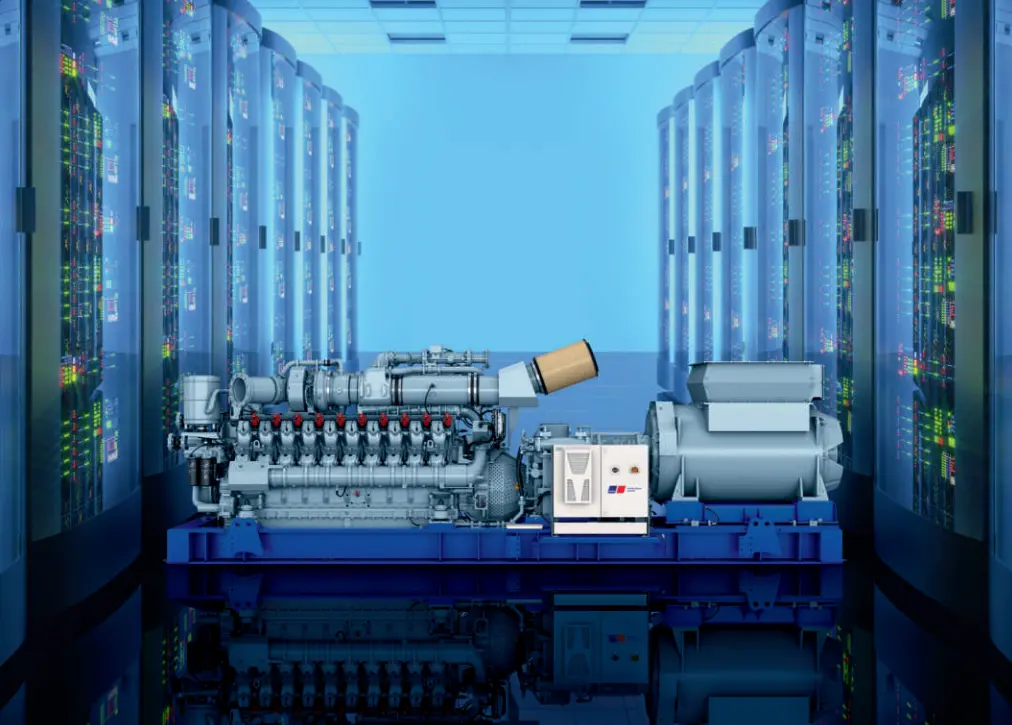

Smart Monitoring with ADEC and Go Connect

The integration of ADEC and Go Connect introduced advanced digital monitoring and analytics, revolutionising how the operator manages performance and maintenance.

- Cylinder-level exhaust tracking for early detection of abnormalities

- Remote diagnostics accessible via PC or mobile

- Historical data comparison enabling informed overhaul decisions

- Alerts and notifications preventing critical failures before they occur

Operational and Cost Efficiencies

| Area | Improvement |

|---|---|

| Spare Parts | Reduced procurement cost and lead times |

| Overhaul Intervals | Extended from ~20,000 to 33,000 hours |

| Maintenance | Shift from reactive to predictive maintenance |

| Fuel Efficiency | Optimised consumption at 199 g/kWh |

| Crew Efficiency | Improved working environment and safety |

| OPEX | Lower costs and increased uptime |

A Strategic Upgrade with Long-Term Value

The repowering of the dredger with the mtu 16V4000M63 engine has transformed it from a high-risk liability into a reliable, efficient, and future-ready vessel.

This case study demonstrates how a targeted investment in modern propulsion and monitoring systems can:

- Resolve fundamental mechanical and operational challenges

- Enhance crew safety and comfort

- Enable predictive maintenance and remote monitoring

- Extend engine lifespan and overhaul intervals

- Strengthen fleet sustainability and profitability

For commercial marine operators, this project is a clear example of how strategic repowering delivers measurable long-term value.