Need help finding the perfect product or system?

No problem at all. Let one of our expert advisors point you in the right direction.

Stay Connected

Sign up for our newsletter

Strategic Solutions for Government Applications

Al Masaood Power Division’s governmental ship propulsion systems are built on a robust commercial marine engine portfolio, with thousands of units successfully operating worldwide. These systems are tailored to meet the specific requirements of naval and governmental vessels, covering a power range from 129 kW to 4,300 kW for diesel engines, and 116 kWe to 3,100 kWe for diesel gensets, ensuring every vessel in your fleet has the ideal propulsion.

Our engines and gensets from world-class partners such us mtu, a Rolls Royce solution, and Volvo Penta, are characterised by high power density, low weight, and compact design, along with exceptional mechanical and thermal stability. They offer straightforward operation, easy maintenance, and low lifecycle costs.

As system partners, Al Masaood Power Division provides extensive expertise in marine applications, encompassing all propulsion configurations, along with the engineering services, hardware, and software required. Whatever your unique requirements, we can deliver a complete, fully integrated propulsion system tailored to your needs.

mtu’s propulsion solutions are designed to power a variety of Governmental authorities, including ferries and high-performance workboats. No matter what your specific needs, you can count on mtu products to deliver efficient and safe operation. We start by providing engineering and technical support for the design and integration of your vessel’s propulsion system.

Our application engineering team focuses on helping you reduce design, installation, and commissioning costs. By integrating a diesel engine, gearbox, on-board power supply, and ship automation, we create a cohesive propulsion system that is both reliable and cost-effective. mtu engines and propulsion systems are known for their high-power density, lightweight design, and excellent responsiveness. They are user-friendly, easy to maintain, and offer low lifecycle costs, all while ensuring extended time between overhauls (TBOs).

mtu‘s portfolio includes a wide range of marine generator sets designed for Governmental authorities’ applications, featuring hybrid solutions and marine diesel generators with outputs from 720 to 3,100 kWe. These systems are suitable for auxiliary and emergency power generation, as well as diesel-electric propulsion. Available in both 50 Hz and 60 Hz configurations, mtu marine generator sets offer various options and accessories, including sound enclosures, control panels, and PTOs for firefighting pump drives. With high operational uptime and intervals between overhauls (TBO) of up to 42,000 hours, our gensets provide cost-effective operation and reliable performance.

As the authorised distributor of mtu products, Al Masaood Power delivers complete solutions backed by factory-trained engineers. We offer both cost-effective, pre-engineered marine gensets developed by mtu’s central engineering team in Germany and custom solutions—including variable speed generator sets—ensuring quality and reliability recognised worldwide.

mtu constant speed gensets are readily available and designed for easy configuration due to their modular design, which helps streamline project timelines. Al Masaood Power’s customers benefit from our service-oriented approach and commitment to support, ensuring their needs are met at every stage.

mtu’s engines are powerful and technologically advanced. To offer the best efficiency, reliability, safety, and environmental compatibility, they need more than just power; they need intelligent electronic management.

Modern engine management systems handle the control and monitoring of the hardware and enable perfect performance. The ship automation systems in the mtu NautIQ portfolio are designed to offer the ideal combination of performance and precision.

The heavy-duty range of marine engines is designed for extreme reliability, ensuring they keep running year after year. Built with robust engine blocks from high-strength castings, large bearing surfaces, and powerful crankshafts, these engines are engineered to withstand the toughest conditions.

Low fuel consumption, minimal maintenance costs, and reduced exhaust and noise emissions are priorities, benefiting both the crew and the environment.

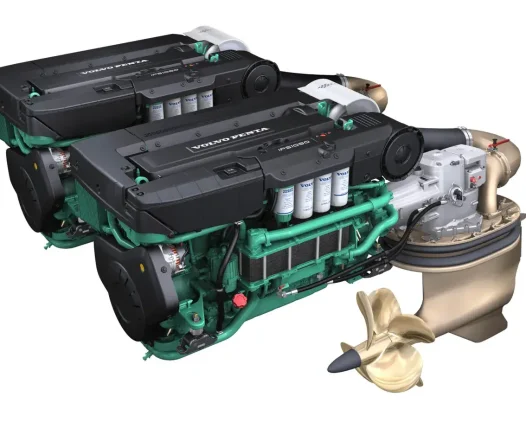

Volvo Penta’s diesel technology delivers exceptional performance without compromising reliability. Whether electronically controlled or mechanically governed, our marine diesels provide the necessary power for quick acceleration and high-top speeds. The current Volvo Penta range offers combinations of high power, low weight, and low emissions that were previously inconceivable.

Diesel inboard engines and marine gensets can also be utilised for various auxiliary applications.

Duoprop is Volvo Penta’s innovative sterndrive, revolutionising marine propulsion with two counter-rotating propellers on a single axis. This design, combined with D4 or D6 engines, eliminates torque steer and enhances handling. The system delivers up to 15% more power, 20% better acceleration, and improved fuel efficiency, while also minimising cavitation and reducing vibration.

Designed to handle the torque of D4 and D6 diesel engines, the DPI Duoprop features silent shifting and smooth manoeuvring at low speeds. Its stainless-steel propellers ensure optimal efficiency and comfort.

The DPH Duoprop is suited for single installations with hydraulic steering, featuring nickel-bronze-aluminium propellers for superior performance.

The Inboard Performance System (IPS) enhances efficiency compared to traditional inboard shafts. Its patented counter-rotating propellers operate in undisturbed water, providing 15% faster acceleration and a 20% higher top speed. Improved fuel efficiency also extends the cruising range by 30%.

The optional joystick simplifies docking and slow-speed manoeuvring, utilising the IPS system’s individually steerable drive units.

With steerable propulsion units replacing fixed propellers and rudders, Volvo Penta IPS directs thrust precisely, achieving a 50% better turning radius and car-like manoeuvrability for effortless docking and predictable handling at speed.

Volvo Penta IPS is a complete system that includes the engine, propulsion unit with gearbox, propellers, exhaust, seawater system, steering, and controls, designed for at least twin-engine installations.

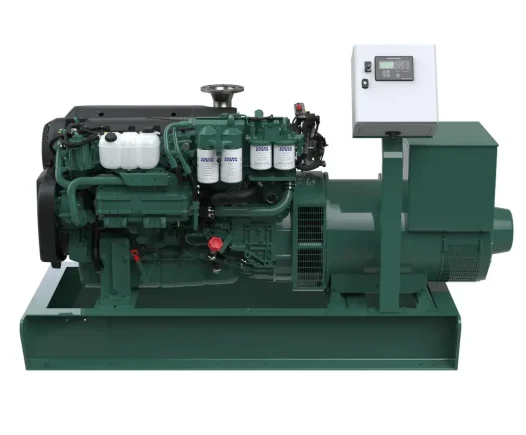

All Volvo Penta gensets are fully tested and delivered ready for installation on board. Each unit is type-approved by major classification societies and can include certification.

Volvo Penta is renowned for its compact engines and gensets that enhance accessibility in engine rooms. Designed for quick maintenance, our engines are compatible with computerised diagnostic tools for efficient troubleshooting. We offer a range of constant and variable speed gensets, factory-built to meet diverse power needs with high efficiency and reliability, ensuring optimal performance in all conditions.

Our control and monitoring system, based on the Modbus protocol, allows for fast and secure integration with most switchboards and power management systems. It features functions such as auto-start, shut-down, and alarms, all complying with international standards.

Our engine range not only meets current exhaust emission regulations but many of our engines already comply with upcoming standards set to take effect in the next few years.

Volvo Penta’s serial hybrid solution leads the way in electromobility, powering MHO-Co’s CTVs, MHO Boreas and Balder. These vessels exemplify engineering excellence, combining electric and diesel technology to push boundaries.

The hybrid systems are designed for flexibility, allowing seamless shifts between electric and diesel modes in dynamic environments like the North Sea. This adaptability enables full electric operation when low power is needed and a swift transition to diesel for higher demands. The strategic integration of batteries with diesel generators makes decarbonised operations feasible while addressing the challenges of heavy and costly full battery packs.

A major advantage of this system is the consolidation of power sources. By using a single engine for all four drive lines, it reduces idle running hours and maintenance costs, enhancing overall efficiency.

No problem at all. Let one of our expert advisors point you in the right direction.

Sign up for our newsletter